LABORATORY INSTRUMENTS FOR CANS, GLASS AND PLASTIC CONTAINERS

Relying on the almost thirty-year-old experience on laboratory instruments for the filling, canning and food industries as well as for the ones related to the production of metal, plastic and glass containers, having furthermore bought an historical brand of the sectors, Parmacontrols recently decided to launch a new range of products named LABOMetrology, enterily egnineered in ltaly with the most innovative technical features but manufactured as per mindful criteria of construction to maintain low their costs.

- Food, beverage, aerosol and general line metal packaging controls

- Automatic and robotized seam inspection systems

- Glass and plastic containers control

- Software SPC

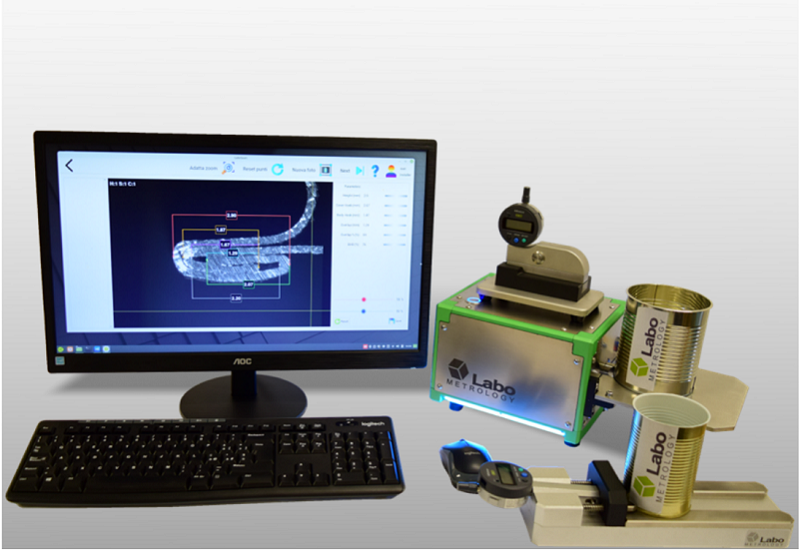

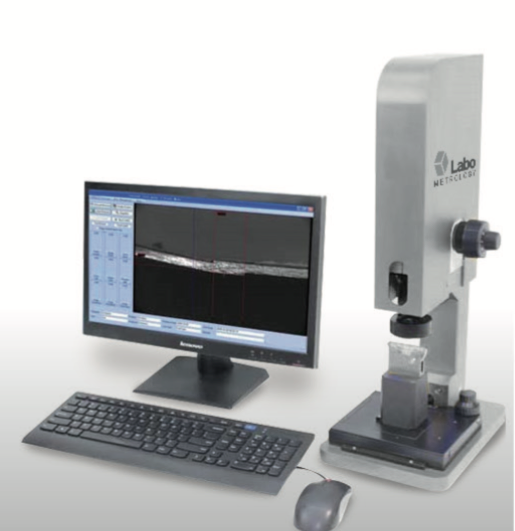

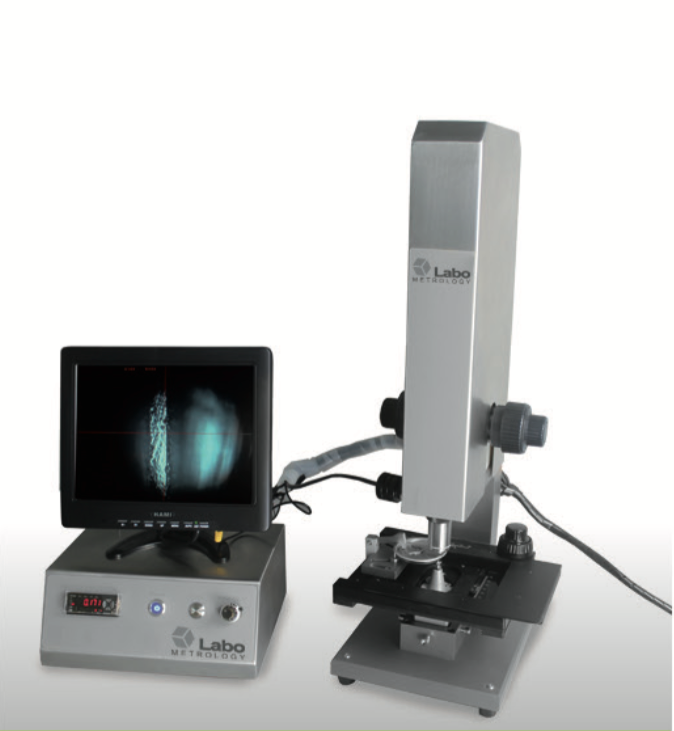

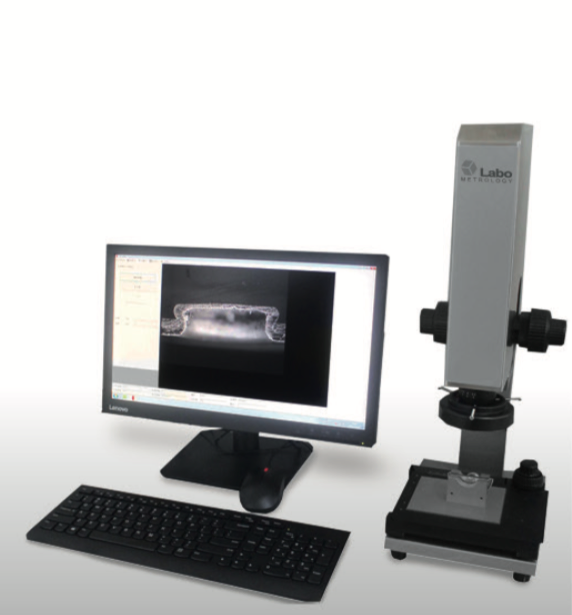

LaboSeam

The inspection system for checking the seams of tin-plate or aluminium cans. The sectioned seaming image is acquired by the high definition camera, shielded against external light interference to obtain the highest accuracy possible. The data of the various measurement points are acquired on the image saved and the results are stored both in image and text format. Any non-standard measurements are immediately highlighted to allow rapid intervention. The results acquired by LaboSeam can be used to create standard or custom reports.

Download technical documentation - Download

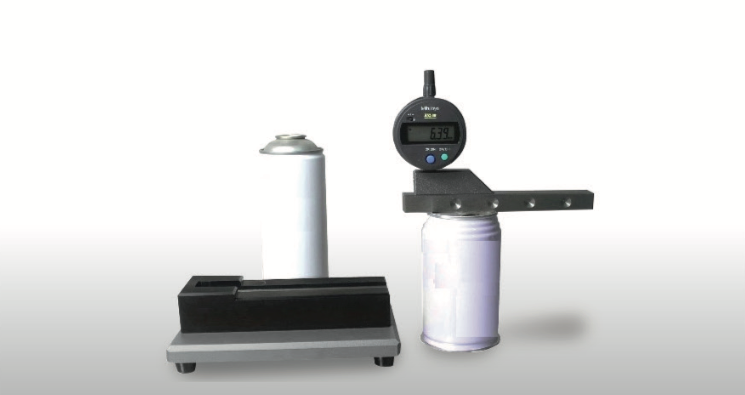

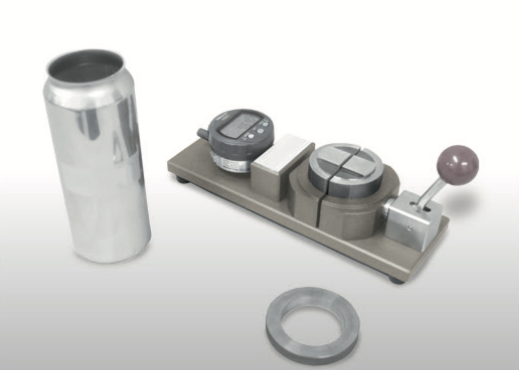

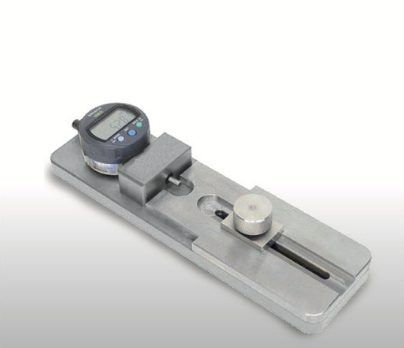

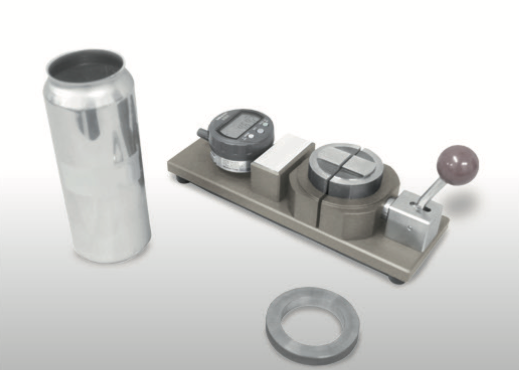

Countersink Check

This is used to measure the depth of the countersink on the can lids and is equipped with a Mitutoyo digital calliper with 0.01 mm resolution. It can be interfaced with the LaboSeam system by connecting the calliper to a PC or SPC system via a USB interface for a complete seaming inspection and check.

Download technical documentation - Download

Seam Thickness Check

This is used to measure the thickness of the seam on the cans and is equipped with a Mitutoyo digital calliper with 0.01 mm resolution. It can be interfaced with the LaboSeam system by connecting the calliper to a PC or SPC system via a USB interface for a complete seaming inspection and check.

Download technical documentation - Download

Multi Seam Cutter

Cutter to section the cans for inspection with the LaboSeam system. Available in four versions, respectively for food, beverage and aerosol cans and for large-format cans (diameter greater than 153mm). The blades are produced so that they guarantee a clean cut without damaging the seam. This allows the LaboSeam system to obtain a clear image and accurate measurement.

VIDEO

Download technical documentation - Download

Seam Stripper

Workbench unit to strip the seam to release the inner ring from the seam to assess the compactness, wrinkles and hook grip. Suitable for food, beverage and aerosol cans. The cutting operation and replacement of the head when changing format are quick and easy.

Download technical documentation - Download

Seamer Pin Height Check

Commonly used in the initial seamer configuration. The instrument allows you to accurately measure the height between the plate and the head to guarantee the formation of the best possible seam.

Download technical documentation - Download

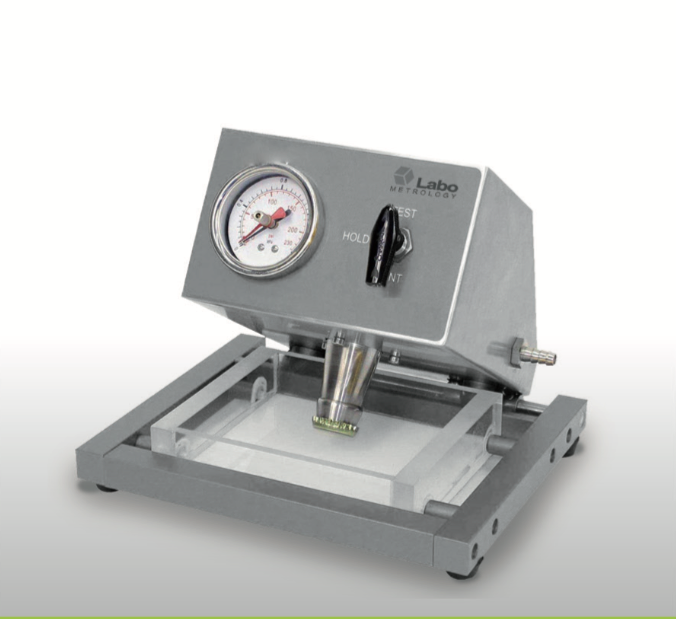

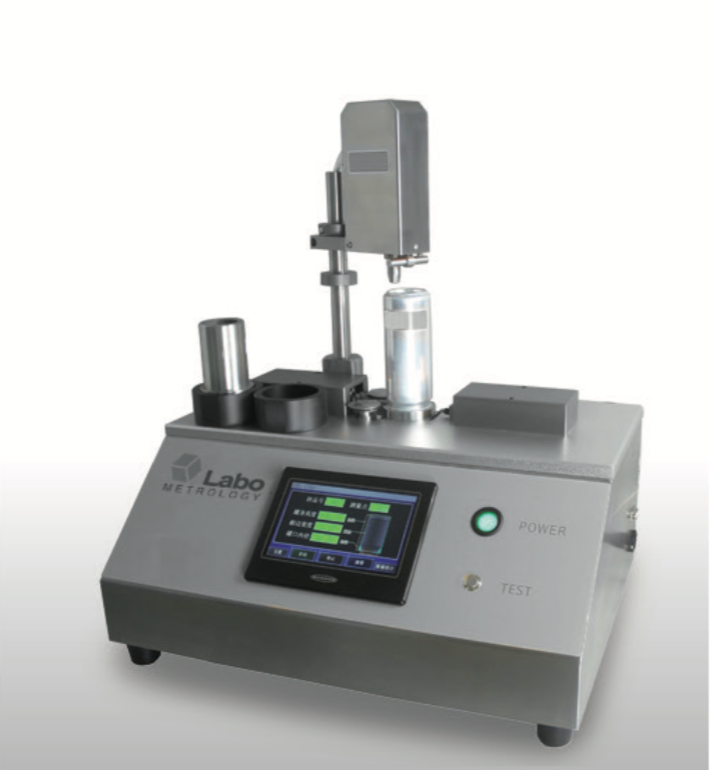

Pressure No Return Check

Instrument for assessing the plastic properties of the can lids under negative pressure. The sample is subjected to positive and negative pressure cycles and its resistance to buckling is measured by a precision micrometer.

The test can be carried out in three different ways:

- PNR - lid extendibility measurement

- BUCKLE – detects the pressure at which buckling is stable

- LENGTH – checks the effect on the lid to a pre-set pressure

Download technical documentation - Download

Top Load Check

It measures the resistance to top load of 3-piece cans. The can is subjected to a progressive force until it buckles. The value of the force at which the can buckles permanently is recorded and displayed.

Download technical documentation - Download

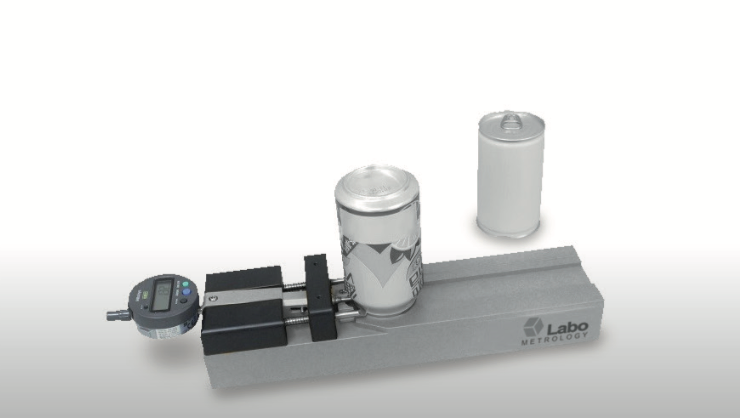

Bead Depth Check

Download technical documentation - Download

Flange Check

Used to measure the width of the can flange. The reliable design allows the operators to take accurate measurements thanks to the special system which allows the positioning of the can to be repeated regardless of the format. The data can be exported a computer or SPC system via the relevant cable and USB adaptor. Available in three versions for cans with a diameter of 50–90 mm, 50–200 mm and 50–300 mm.

Download technical documentation - Download

Digital Height Check

Device for measuring the height of rigid containers. Used to measure the height of food and beverage cans, glass and PET bottles and plastic containers. The base on which the container is placed which is perfectly flat since it is made of rectified steel is also used as a reference for homing the system. The calliper can be connected to an external computer or SPC system via the relevant communications interface.

Download technical documentation - Download

Inner Diameter Check

Used to measure the inner diameter of 2/3-piece cans. Available in three versions for cans with different diameters ≤ 69 mm (211), ≤ 105 mm (404) and ≤ 153 mm (603).

Download technical documentation - Download

Welding Overlap Check

Vision system for assessing the overlap and welding seam thickness. Used to measure the length, thickness and any other defects caused by the overlap of the side weld seam. It is fitted with an advanced optical system and lens which ensures a high-definition image. The measurements acquired directly on the image can be saved on a PC, imported into an Excel spreadsheet and printed.

Download technical documentation - Download

Weld Seam Ball Check

Strength and tightness check of pressure welding. Used to test the strength and continuity of the side weld seam of 3-piece cans. The weld seam is subjected to pressure to assess its strength and hold.

Download technical documentation - Download

Welding Line Outstretch Check

Strength and tightness check for weld line outstretch. Used to test the strength of the flange weld. The can body is subjected to external bending to assess the strength of the hold. This method is often used alongside the production line.

Download technical documentation - Download

Leak Check Can

Instrument to test the tightness of cans subjected to inner pressure. Used to check the tightness of opened 3-piece cans. The can is sealed with a special waterproof lid and immersed in a water bath by a pneumatic lifting/lowering system. Pressurised air is introduced into the can. If there are any leaks, the formation of bubbles in the water bath can be detected. Available in three versions to test respectively one, three or six cans simultaneously.

VIDEO

Download technical documentation - Download

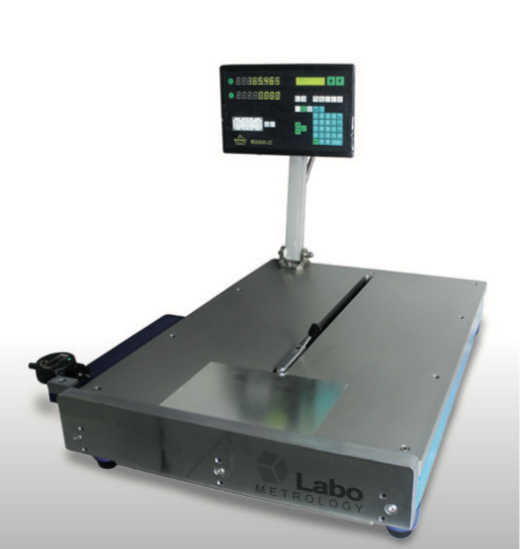

Body Blank Check

Dimensional check of sheets. Performed to measure the length, width and perpendicularity (angle) of the tin-plate bands. The measurements can be exported to a PC or SPC system with the data output interface. Available in three versions with the following measurement ranges (0 - 370 mm; 0 - 550 mm; 0 - 900 mm)

Download technical documentation - Download

Semiautomatic Check Bench

Automatic station for checking lid dimensions. The instrument simultaneously measures the four parameters to check the production quality of tin-plate or aluminium lids:

- external curl diameter

- curl height

- countersink depth

- drawing depth

The data are saved in the internal memory of the instrument and can be exported to an external PC.

Download technical documentation - Download

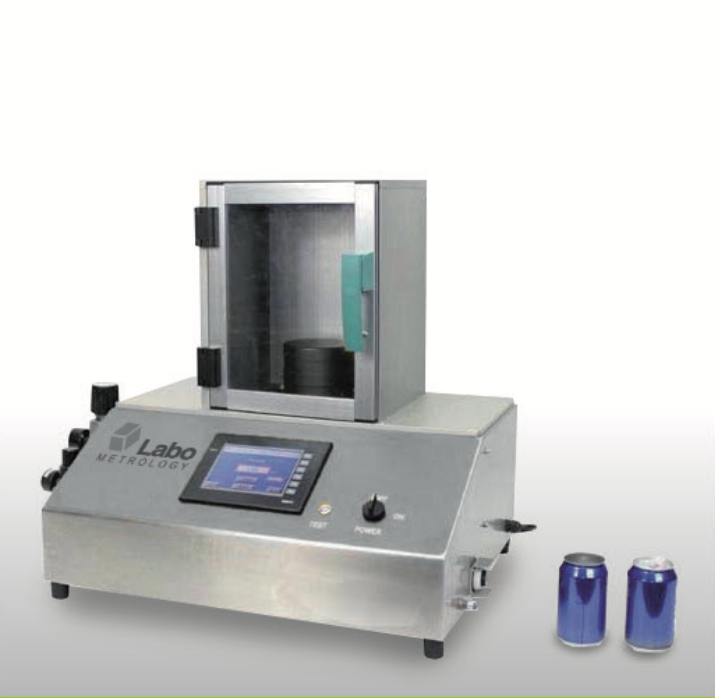

Buckle Check

Measures the lid buckling/break force. Used to test the exact pressure at which the lid buckles and/or breaks. A wide range of supports with different measurements is available which can be swapped over in just a few seconds.

The instrument can operate in three different modes:

- Buckle Test: in this mode, the pressure at which the lid buckles is detected,

- Missile Test: specifically for high pressure containers and consists of detecting the conditions under which the lip loses its hold and separates from the lid at high speed

- Score Burst Test: in “Burst” mode, the lid breaking point is detected.

Download technical documentation - Download

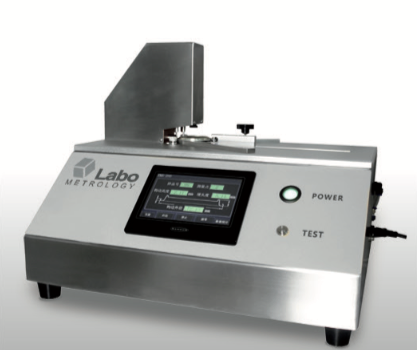

Pop & Tear Check

The PTT (Pop & Tear Tester) automatically measures the opening, rotation and tear-off force of lids with a pop and tear system (RP - SOT - EO - FSE - OVAL - ALUFIX - SNAP). The instrument is used in the production of lids for the food and beverage industry and can be mounted on specific supports for shaped cans.

The operation of the instrument is very simple: just attach the ring of the lid with the special hook and start the test which will proceed automatically. The measurement can also be displayed in diagram form and it is possible to assess the value measured point by point on the screen.

Download technical documentation - Download

Micro Score Check

The instrument allows you to measure the depth of the score and the thickness of the residual metal in easy open lids.

The image is acquired by a microscope with a high-definition camera. The score depth measurement (about 70% of the thickness) is measured by a micrometric system with an accuracy of ± 1µm. The data are automatically saved.

Download technical documentation - Download

Rivet Check

Instrument for checking the rivet. The lid, sectioned by a low speed cutter in line with the rivet, is positioned on the microscope translation stage with a high-definition camera. Once the image has been acquired on the screen, it is possible to assess the structural and functional parameters of the rivet.

Download technical documentation - Download

Low Speed Cutter

Low speed lid cutter. Used to obtain a cross-section of the lid which includes the anchor point of the ring (rivet) so the structural regularity and construction parameters can be examined under a suitably adapted microscope. The low speed at which the cut is carried out allows a perfectly flat and even inspection surface to be obtained.

Download technical documentation - Download

Curl Diameter Check

The instrument is used to measure the diameter of the curl and can be used on any lid, both round and rectangular. The instrument can be connected to a computer or SPC system via the adaptor and cable.

Download technical documentation - Download

Curl Height Check

Digital calliper for measuring the height of the curl and can be used both for round and rectangular lids. The instrument can be connected to a computer or SPC system using the relevant communications interface.

Download technical documentation - Download

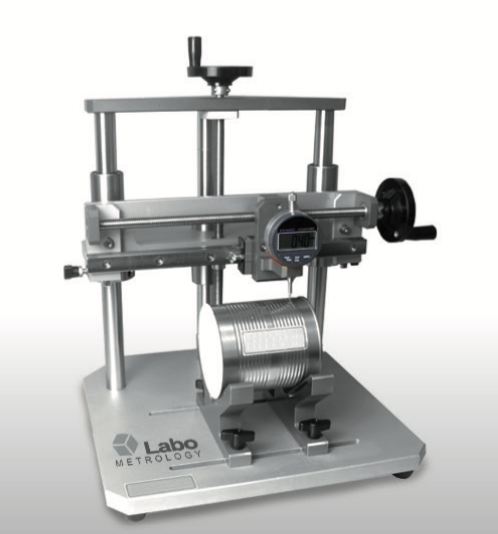

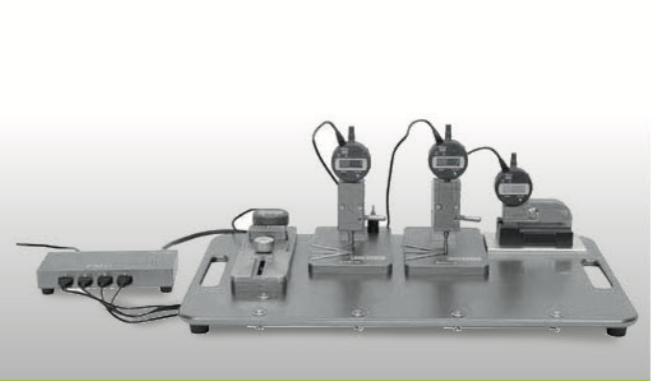

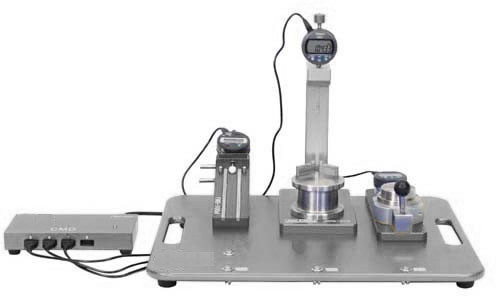

Check Bench

It is possible to check the height, diameter, curl depth and countersink depth on a single workbench. Each micrometer is connected to a Mitutoyo digital indicator with a resolution of 0.01 mm that can be connected to an external computer or SPC system for data collection via a communications interface.

Download technical documentation - Download

Leak Check End

Instrument for assessing lid tightness. It is used to determine the buckle pressure of the lids by subjecting them to increasing pressure until they buckle. It can also be used to check for leaks in the rivet insertion point and in the incision area. Supports are available for various sample diameters. It is easy to use and can test two lids at the same time.

Download technical documentation - Download

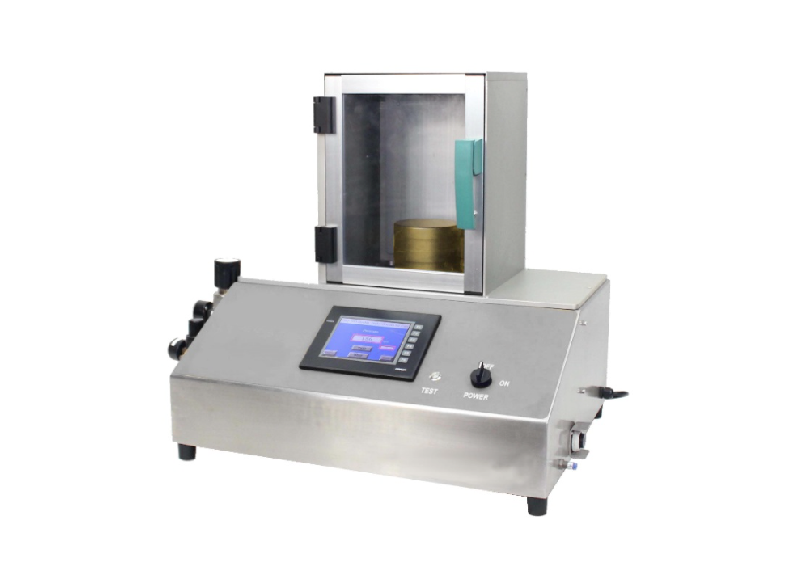

Burst Check Aerosol

Instrument to check the tightness and resistance to pressure of aerosol cans. It is used to test the buckle and burst pressure of aerosol spray cans. The sample is secured with special clamps and it is possible to check the buckle point of the bottom and the dome to detect the most critical point.

When the pressure exceeds the resistance limit of the sample, the upper and lower part expand and; at maximum pressure, the can explodes, terminating the test. It is possible to view the pressure curve, peak value, pressure maintenance time, etc. on the touch screen.

Download technical documentation - Download

Leak Check Aerosol Single and Multi

Instrument to check the seal of aerosol cans. It is used to check the seal of aerosol containers through immersion in water. It tests one aerosol can at a time. The can immersed in the water is subjected to a gradual increase in pressure and the value is indicated on the measuring device. Every can is rotated so that the point where any air escapes can be checked accurately, thus identifying the defect. Once the set holding time has expired, the can is automatically raised and the test concluded.

The instrument is available in three different versions, with 1, 6 and 8 measurement points respectively.

Download technical documentation - Download

Cap Seal Check

Instrument used to assess the tightness of crown caps. The cap is mounted on the bottle neck of the machine using the same methods of a normal bottling process, immersed in water and subjected to positive pressure from the inside. If not perfectly tight, it will be possible to detect to air bubbles escaping.

Download technical documentation - Download

Tumbling Check

Instrument used to check the abrasion resistance of crown caps. A sample of 25 caps is weighed and tumbled for the set time and subsequently, weighed again at the end to assess the weight loss.

Download technical documentation - Download

Enamel Rater Single

Electrochemical analyser to measure the thickness and discontinuities of the inner coating of metal containers. The instrument is used to measure the porosity, thickness and adherence of the internal coating of metal containers for food and beverage products. It is also possible to detect accidental defects, such as the loss of coating around the seam, weld or drawing out point, as well as the presence of scratches or abrasions. The instrument measures the electric current that passes through the sample; the quantity of current detected is proportional to the thickness of the coating (compactness) and/or the defects (discontinuity) of the internal coating.

The test is carried out on 2 or 3-piece cans, aerosol cans and lids.

VIDEO

Download technical documentation - Download

Enamel Rater Multi

Electrochemical analyser to check the internal coating of the lids. It is used to test the integrity of the inner coating (internal coating density and current value). There are two models for 10 and 20 stations. The test time is 4 seconds.

Download technical documentation - Download

Coat Thickness Check

Instrument to measure the thickness of the coating inside metal containers. The surfaces of the metal containers for food and beverages are normally coated both internally and externally. This instrument allows you to rapidly measure the thickness of the inner and outer coating of beverage cans, tin-plate cans and sheets. The measurement is indicated in g/m2.

The instrument can be connected to two different probes to take measurements on the can body or the metal sheet before cutting.

VIDEO

Download technical documentation - Download

Abrasion Check

This instrument is used to assess resistance to wear and abrasion of the outer coating of cans. The cans are fixed on the test support and subjected to a series of movements which simulate the stress that occurs during transport. Once the test conditions have been set (range of movements, test time), the effects on the sample are assessed.

Download technical documentation - Download

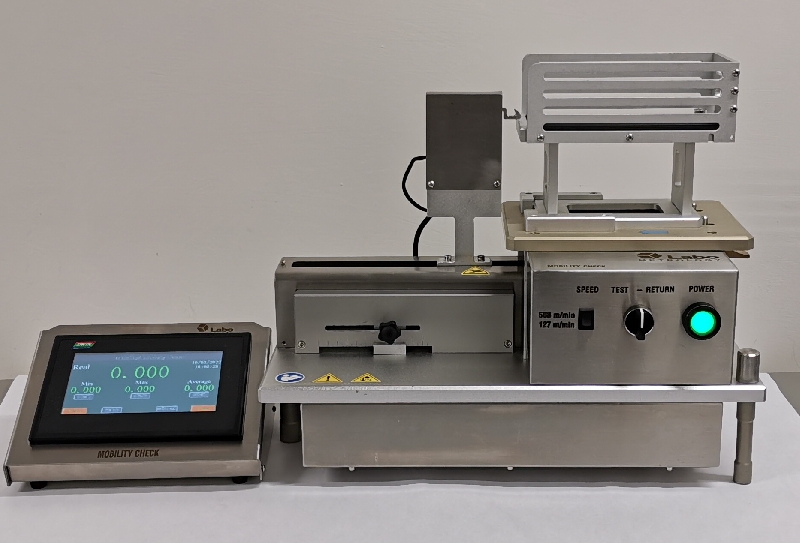

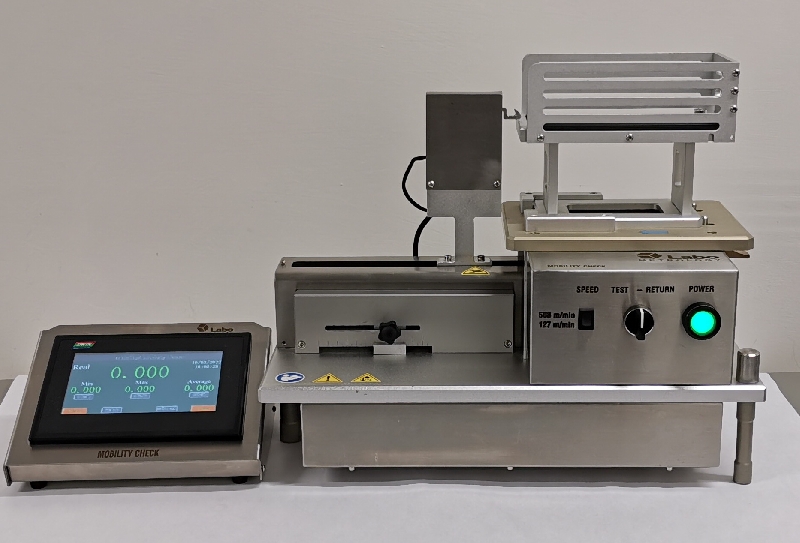

Mobility Check

Instrument to check mobility (sliding). The can lubrication tester is used to measure the sliding friction coefficient on the body and base of the can. It can also measure the sliding friction coefficient of empty spaces. A special feature is the possibility to select a dedicated data transmission mode by sending the measured values to an external PC (1 sample value for each millimetre).

Download technical documentation - Download

Scratch Resistance Check

Instrument to test scratch resistance. It is used to determine the resistance of single or multiple coatings of enamel, or similar products, to penetration through scratching with a needle with a semi-circular point, an abrasion instrument or a metal scratching tool.

Download technical documentation - Download

Burst Check Glass S/D

The automatic system with one or two stations designed to run pressure tests on glass containers. The current system is very versatile and can be used to run pressure tests using all the methods specified in the standards required by the glass industry. The bottle grip is adjustable and adaptable and does not require any tools for a format changeover. The machine set-up is intuitive, the recipes for each format are easily managed by all operators and the data transmission system is compatible with all the data collection and management systems typically used in the glass industry (e.g. Vertec).

VIDEO

Download technical documentation - Download

Vertical Load Tester

Vertical load simulator for glass bottles. The instrument measures the vertical load of glass containers, simulating the force to which the bottles are subjected during capping and storing operations. The device is controlled via PLC and displayed and checked via a touch screen. The data are recorded and can be exported to an external database.

Download technical documentation - Download

Impact Tester

Instrument for testing impact. It is the standard sector-based instrument for testing the resistance to impacts of glass containers. The test measures the impact energy and angle of the pendulum rod. Packaging can also be tested with non-circular cross-sections by changing the accessories. The structure and use of the instrument meet the requirements of “GB6552-86 - Methods for impact resistance of glass containers”.

Download technical documentation - Download

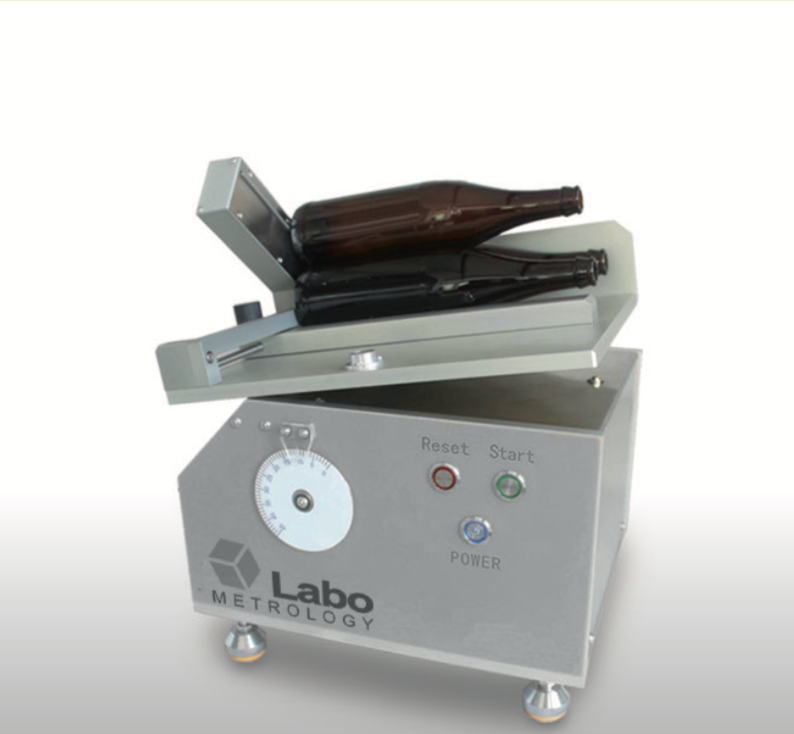

Friction Angle Check

Used to determine surface lubrication. It allows an accurate measurement of the lubrication power and the static friction coefficient on the surface of the container. Three containers are placed on the inclined surface of the instrument in a pyramid shape. The electric motor gradually increases the inclination angle of the surface to which the two lower containers are secured and do not move during the test. When the inclination angle becomes great enough to overcome the forces of friction between the containers, the top container starts to slide and enters into contact with the trigger sensor which stops the drive motor and simultaneously, applies a brake to the inclined table. This prevents arrest by inertia and inadvertent measurements of incorrectly high inclination angles.

VIDEO

Download technical documentation - Download

Bottom Thickness Check

The instrument is used to measure the thickness of the bottom of glass bottles. It has a digital indicator with a resolution up to 0.01 mm.

Download technical documentation - Download

Wall Thickness Check

It has a digital indicator with a resolution up to 0.01 mm and is used to measure the thickness of the walls of glass bottles.

Download technical documentation - Download

Verticality Check

It is used to measure the verticality deviation of glass bottles. Fitted with a high-precision rotating locking plate, Mitutoyo digital indicator, automatic calculation display and platform with column, the instrument allows you to directly display and save the data.

Download technical documentation - Download

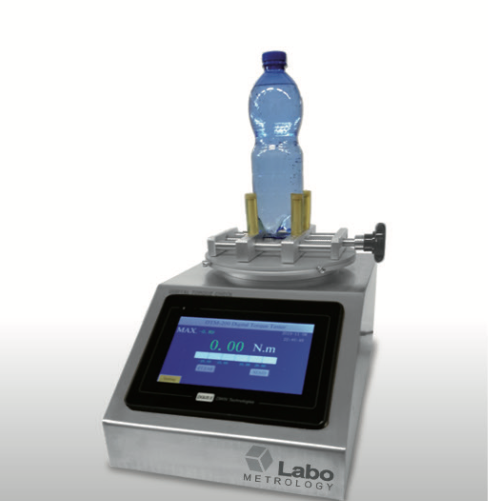

Automatic Torque Check

The automatic torque tester is intended for testing torque (both on opening and on closing) without the intervention of the operator and in standard conditions of repeatability. The torque tester can be used in the laboratory or on the production line where it is necessary to standardise the test conditions and manage the results for fine-tuning the capping system and quality control of the line. The instrument saves the test reports and statistical data analyses (minimum, maximum, average value, standard deviation). It has a communications port for an external computer or printer.

VIDEO

Download technical documentation - Download

Digital Torque Check

The Torque Tester (DTC) is a professional, standardised instrument for measuring the torque strength of caps and capsules used to close bottles, preforms, glass jars and plastic containers. It is used for fine-tuning and checking capping machines.

It is possible to measure both the opening and closing force of the container.

The measurement can be expressed in Kgf.cm/Inch.lbs/daN.cm/N.cm/N.m

Download technical documentation - Download

Burst Check Plast

This instrument measures the resistance to pressure of PET bottles and allows you to check if the bottle is qualified to meet the production requirements requested.

The instrument can operate according to three different standard test programs:

- fill ramp mode: the sample is subjected to different pressures and times to assess the seal under the conditions set

- burst mode: the sample is subjected to increasing pressure until it bursts

- custom mode: it is possible to set the test characteristics according to the operator’s specifications

Download technical documentation - Download

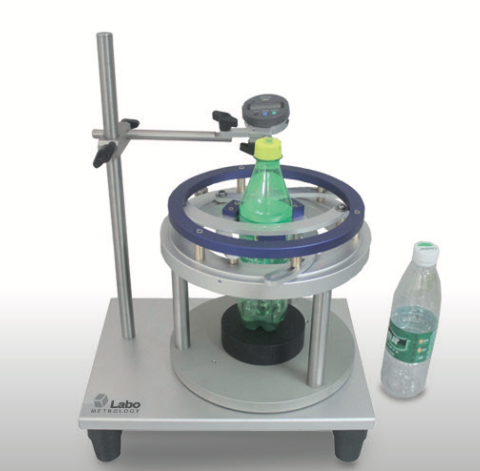

Top Load Check PL

The sample is secured to the test support where it must withstand the weight of a greater load. The measurements that can be taken are: load resistance, buckling, crush resistance and buckling of the side walls of the bottle.

The instrument is practical and easy to maintain, providing useful data for quality control to improve the product.

Download technical documentation - Download

Base Clearance Check

The instrument is used to measure the distance from the base (height of the dome to the lower part) of PET bottles. The results are displayed on an integrated digital indicator.

Download technical documentation - Download

Verticality Check PET

Complete with rotation clamps, digital indicator and calibration column, it is used to measure the verticality of PET bottles. It is the industry standard in the production of PET bottles and in the beverages industry.

Download technical documentation - Download

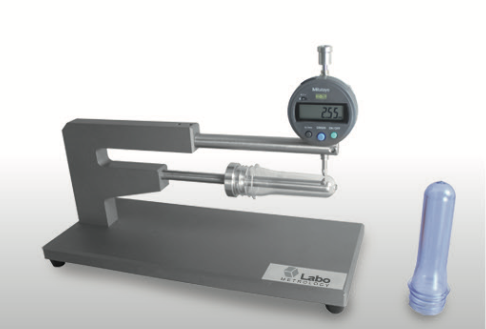

Verticality Check PRF

It is used to test the verticality of preforms. It is the standard equipment for the PET bottle industry and beverages industry. This instrument consists of a rotating clamp, indicator, calibration column and vertical column and guarantees absolute precision. The rotating clamp can be customised and replaced. Special calibration columns and clamps are required for preforms with openings of variable diameter.

Download technical documentation - Download

Digital Height Check

The instrument is used to measure the height of plastic and PET containers, in addition to containers for beverages, food and aerosol containers, using the same homing platform. The base on which the container is placed which is perfectly flat since it is made of rectified steel is also used as a reference for homing the system. The calliper can be connected to an external computer or SPC system via a communications interface.

Download technical documentation - Download

Thickness Gauge

It is used to measure the thickness of a PET preform. The measurement pressure is adjusted mechanically so that the result is not altered by operator intervention. This calliper consists of a measurement clamp and a digital indicator and can be adapted to different size preforms.

Download technical documentation - Download

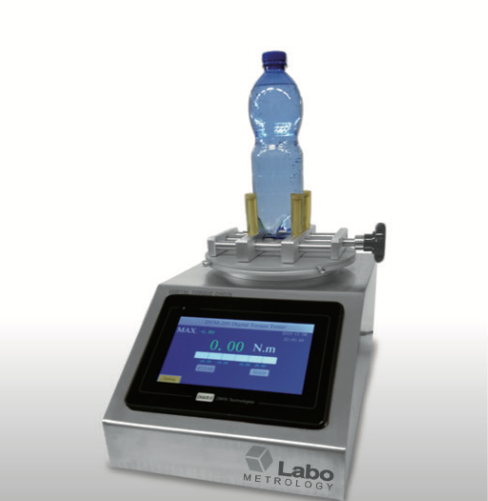

Automatic Torque Check

The automatic torque tester is intended for testing torque (both on opening and on closing) without the intervention of the operator and in standard conditions of repeatability. The torque tester can be used in the laboratory or on the production line where it is necessary to standardise the test conditions and manage the results for fine-tuning the capping system and quality control of the line. The instrument saves the test reports and statistical data analyses (minimum, maximum, average value, standard deviation). It has a communications port for an external computer or printer.

VIDEO

Download technical documentation - Download

Digital Torque Check

The Torque Tester (DTC) is a professional, standardised instrument for measuring the torque strength of caps and capsules used to close bottles, preforms, glass jars and plastic containers. It is used for fine-tuning and checking capping machines.

It is possible to measure both the opening and closing force of the container.

The measurement can be expressed in Kgf.cm/Inch.lbs/daN.cm/N.cm/N.m

Download technical documentation - Download

Hot Wire Cutter

The HWC is used to simultaneously cut the plastic container into multiple sections in a simple and efficient manner to analyse the weight of the section. It can cut PET bottles into several specific sections (maximum 5 sections). So, the user can check if each section falls within the corresponding standard weight.

Download technical documentation - Download

Seal Check

Instrument for checking the tightness of the closure. The Seal Check is used to check the integrity and strength of the closure in beverage cans, glass bottles with plastic closures or capsules or crown caps and PET containers (bottles, preforms, plastic bottles). The container is immersed in water and subjected to internal pressure via a punch which pierces the closure. The closure is deemed correct if there is no air bubble leak to the pressure applied. The instrument comes in two versions: one or three working positions.

Download technical documentation - Download

Automatic Front End Check

Instrument to automatically measure the external parameters of the front side of the can body. The instrument, designed on the basis of extensive experience in the sector, is used to measure the depth of the base, the height of the can and thickness of the walls in two different points. It can be rapidly adjusted and is applicable to cans of different heights. The 3 pneumatic control sensors automatically measure the sample which rotates when the measurement starts. A maximum of 50 measurement points can be set in one rotation. The instrument is controlled by an internal PLC unit with touch screen; the results can be exported to a PC via RS232 cable.

Download technical documentation - Download

Bottom Depth Check

Instrument to measure the depth of the bottom of beverage cans. With this instrument, it is possible to measure the depth of the bottom of the can compared to the edge to check compliance with the production parameters entered. The measurement is taken by a Mitutoyo digital indicator with a resolution of 0.01 mm on a special support. It is possible to connect the measurement instrument to an external computer via a communications interface.

Download technical documentation - Download

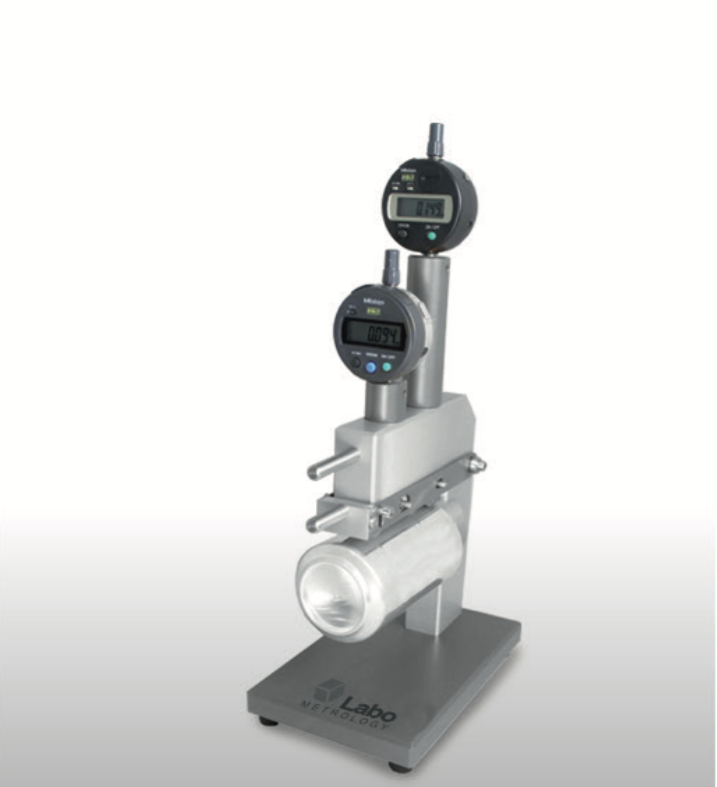

Wall Thick Check

Instrument to measure the thickness of the can body. The thickness measurement of the can body in different points is a very important parameter in the quality control in the process of producing the can. The measurement is taken by a pair of Mitutoyo digital indicators with a resolution of 0.01mm mounted on a special support. It is possible to connect the measurement instrument to an external computer via a communications interface.

Download technical documentation - Download

Inner Diameter Check

Used to measure the inner diameter of 2/3-piece cans. Available in three versions for cans with different diameters: ≤ 69 mm (211); ≤ 105 mm (404); ≤ 153 mm (603).

Download technical documentation - Download

Automatic Back End Check

Instrument to automatically measure the external parameters of the open side of the can body. The instrument is used to measure the diameter of the flange, the height of the can and diameter of the 2-piece can body opening. It is designed from practical experience and applied to back-end inspection. It can be rapidly adjusted for any format. The 3 pneumatic control sensors automatically measure the sample which rotates when the measurement starts. For every rotation, a maximum of 50 measurement points can be set. The instrument is controlled by an internal PLC unit with touch screen; the results can be exported to a PC via RS232 cable.

Download technical documentation - Download

Back End Check

Workbench to measure the structural parameters of 2-piece can bodies. This measurement bench combines three instruments in one support:

- Wall Thick Check - measures the thickness of the wall

- Bottom Depth Check - measures the depth of the bottom

- Can Height Check - measures the height of the can

The three instruments can be connected to the external interface to transmit data to an external computer or SPC system

Download technical documentation - Download

Top Load Check

Instrument for measuring the top load. It measures the resistance to top load of 2-piece cans. The can is subjected to a progressive force until it buckles. The value of the force at which the can buckles permanently is recorded and displayed on the screen.

Download technical documentation - Download

Buckle Check Cans & Ends

Instrument to measure the pressure at which the cans are buckled. The sample is subjected to increasing pressure up to the set value. It is possible to determine the exact pressure at which buckling occurs based on the supports and sensors activated. The instrument operates in four different modes:

- buckling pressure of the bottom

- buckling pressure of the loose lid

- rivet detachment pressure (missile test)

- buckling pressure of the seamed lid

Download technical documentation - Download

Burst & Buckle Check

Instrument to measure the pressure at which the cans are buckled and the pressure at which they burst. The sample is subjected to increasing pressure (the increase in speed is set by the operator) until the buckling of the sample is detected. By increasing the pressure further, the value at which the can bursts is reached. It is possible to check the buckling and burst pressure of the sample with this test, as well as the quality of the materials, the quality of the production procedures, such as rivets and seams. The Burst & Buckle Check is an excellent instrument for checking the quality of the production of cans and lids.

Download technical documentation - Download

Mobility Check

Instrument to check mobility (sliding). The can lubrication tester is used to measure the sliding friction coefficient on the body and base of the can. It can also measure the sliding friction coefficient of empty spaces. A special feature is the possibility to select a dedicated data transmission mode by sending the measured values to an external PC (1 sample value for each millimetre).

Download technical documentation - Download

Abrasion Check

Instrument to assess the resistance to abrasion of the can body. This instrument is used to assess resistance to wear and abrasion of the outer coating of cans. The cans are fixed on the test support and subjected to a series of movements which simulate the stress that occurs during transport. Once the test conditions have been set (range of movements, test time), the effects on the sample are assessed.

Download technical documentation - Download

Automatic Seal Check

The tightness checking system is used to check the integrity of the closure of containers along the production lines with the aim of automating the quality control and minimising operator intervention and inevitable measurement uncertainties due to interpretation errors. The instrument detects any leaks of the gas introduced at regulated pressure into the closed container and thus, checks the integrity of the closure. It is used to check PET bottles, cans, glass bottles with crown caps as well and glass jars with capsules. It is possible to set the test pressure, detection limit and flow rate for each production programme. The data displayed can be exported to an external computer and analysed with SPC software.

Download technical documentation - Download

Seal Check

Instrument for checking the tightness of the closure. The Seal Check is used to check the integrity and strength of the closure in beverage cans, glass bottles with plastic closures or capsules or crown caps and PET containers (bottles, preforms, plastic bottles).

The container is immersed in water and subjected to internal pressure via a punch which pierces the closure. The closure is deemed correct if there is no air bubble leak to the pressure applied.

The instrument comes in two versions: one or three working positions.

Download technical documentation - Download

Pierce & Sample

Sample with needle. The instrument is used for product sampling mainly to measure the O2 dissolved in bottles and cans and to measure the stability of foam in beer.

Download technical documentation - Download

CO2 Check with Shaker

Instrument to measure the CO2 in large containers. The measurement of CO2 in carbonated drinks based on the ratio of pressure and temperature is known as the “ASBC theory” of the American Society of Brewing Chemists, the equivalent of the “GB / T 4928 - 2001 Brewing Analysis Methods” and “GB / T 10792 - 1995 Carbonated Beverage Analysis Methods”.

The test involves releasing CO2 from the solution by shaking. This instrument has been designed to shake the sample mechanically instead of manually. The benefits are obvious, especially if large samples need to be analysed. The use of a mechanical device also allows standard operating conditions to be enforced.

Download technical documentation - Download

CO2 Check & Pressure Check

Instrument to measure CO2. The sample is placed on base of the support and pushed upwards through a special mechanism until it is pierced by the punch mounted on the pressure gauge. The instrument directly calculates the concentration value of CO2 in carbonated drinks based on the pressure values and temperatures measured. The instrument can be used to test 2-piece cans, PET bottles and glass bottles. The instrument can also be connected to the AirMeter extractor to measure residual air.

Download technical documentation - Download

CO2 & Pressure Check

Instrument to measure CO2. The sample is placed on base of the support and pushed upwards through a special mechanism until it is pierced by the punch mounted on the pressure gauge. By showing the pressure and temperature values on the ruler, it is possible to obtain the CO2 concentration value in carbonated drinks. The instrument can be used to test 2-piece cans, PET bottles and glass bottles.

Download technical documentation - Download

Labo Data

Management tool for collecting data from different kind of instruments. It supports the creation of multiple users and the set up of their relevant levels of access to the program's feature. The data collected can be exported only in text and/or PDF format.

Download technical documentation - Download