FOOD & BEVERAGE INDUSTRIES PACKAGING INSPECTION

Parmacontrols manufactures its own dedicated line of controls for the canning, bottling and packaging industries, called HiControls, entirely complementary and integrated with the other technologies distributed and described above. Offering customized solutions designed and built for specific customer needs, Parmacontrols can manage applications and installations however difficult, and with the flexibility of a small company can offer tailor-made solutions that larger companies cannot achieve.

- Bottles (EBI), jars and empty cans control systems

- 360° total labels inspection on containers: cans, jars, bottles

- In-line Seam inspection

- XR, HF and Laser level control

- Vacuum and pressure control

- Camera inspection for plastic and pharmaceutical containers, OCV/OCR control

- Single and multipush rejectors

- Weight control

- Remote assistance service

Linear ControlVision

New design inspection machine for empty glass bottles and jars. It can be easily inserted in the existing layout and does not require format changeover equipment. Allows for significant savings on installation costs. Control of lip, bottom and walls.

VIDEO

Download technical documentation - Download

ControlCamera Plastic

Complete inspection for transparent and opaque containers. Up to 6 high-resolution cameras for maximum inspection quality with minimum false rejects. Control of mouth, bottom and walls.

VIDEO

Download technical documentation - Download

ControlCamera Finish

Inspection system with cameras to control the lip/thread in glass and plastic jars and bottles.

VIDEO

Download technical documentation - Download

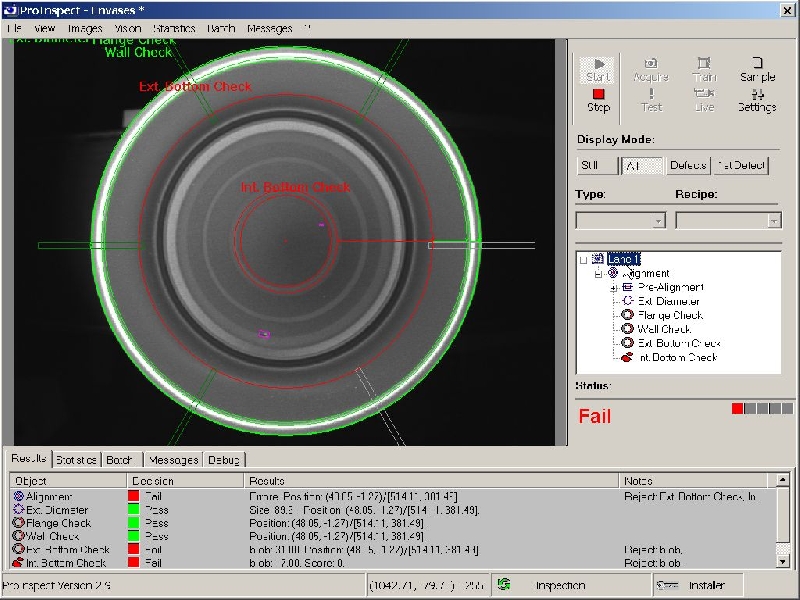

ControlCamera Cans-ICI

Inspection of empty cans: check of flange, oval shaping, defects and marks on inner surface.

Download technical documentation - Download

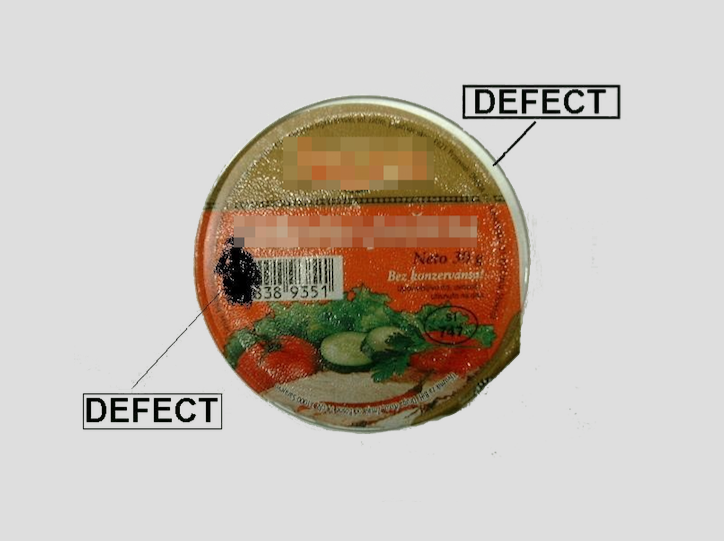

ControlCamera Deco&Seam 360°

Inspection of empty cans, seamed cans and 360 degree seam inspection with multiple cameras.

Download technical documentation - Download

ControlCamera Label 360°

Inspection of finish of different bottles and containers for the verification and overall control of the labels. Up to 4+1 cameras used.

Download technical documentation - Download

ControlCamera Label

Unit for the inspection of partial or total labels in shaped or positioned containers, in general. The number of cameras and their location depends on the type of inspection and control required.

Download technical documentation - Download

ControlCamera Shape-Sorter

Control of the shape and dimensions for all types of containers.

VIDEO

Download technical documentation - Download

ControlCamera Caps

Control unit with cameras for the inspection of all types of caps/closures. The number of cameras, up to a maximum of 3 positioned at 120°, depends on the required checks.

VIDEO

Download technical documentation - Download

ControlCamera CODE

Inspection unit to check the quality and readability of CIJ and laser-marked codes, barcodes, matrix codes, in cans, jars, briks and all types of containers and packaging.

Download technical documentation - Download

ControlCamera Pharma Cosmetic

Control system for the correct assembly and presentation of products in the packaging lines of the pharmaceutical and cosmetic sector. Consisting of several control units each equipped with up to 3 cameras, designed and engineered to fulfil different tasks.

VIDEO

Download technical documentation - Download

ControlCamera Cans-OR

Control unit with camera for recognising the positioning of boxes with Easy Open or tapered lid. It can work with high tolerance to variations in brightness and partially compensate for the presence of dirt or water drops on the surface of the box.

VIDEO

Download technical documentation - Download

ControlCamera Foil

Inspection machine with camera that allows you to check the position of the closing foil on aluminium or thermoformed trays to reveal any movements that indicate a potential leak. It can also verify defects on the lithography so it is also possible to identify prints that correspond to different products.

Download technical documentation - Download

ControlCamera Crate

System with one or more cameras able to verify the presence of a pre-set number of objects inside crates and cartons.

Download technical documentation - Download

ControlLevel HF

Minimum and maximum level control system for liquids or fluids in glass or plastic containers, of any shape and colour, transparent or opaque. It uses capacitive high frequency sensor technology. Options: cap check and label/s check.

VIDEO

Download technical documentation - Download

ControlLevel X-RAYS

Minimum/maximum level control system for liquids or fluids in glass, plastic or metal containers of any shape and colour. It works by using X-ray absorption monitoring as a measuring principle.

VIDEO

Download technical documentation - Download

ControlLevel Laser AC

Level (volume) control system of solid, liquid or dark fluid products in open containers of any material, shape and colour, transparent and opaque. It uses high-precision, high-frequency scanning laser light sensor technology.

VIDEO

Download technical documentation - Download

ControlLabel/Cap

Control for cap, lid, wirehood, capsules with photocells and/or sensors. Control for presence of labels with dedicated photocells and sensors, both in the labeller and stand-alone stations.

Download technical documentation - Download

ControlVacuum/Pressure

Control of vacuum/pressure (lid/capsule concavity/convexity) in metal containers, also with easy-open lid and in jars/bottles with metal capsule.

VIDEO

Download technical documentation - Download

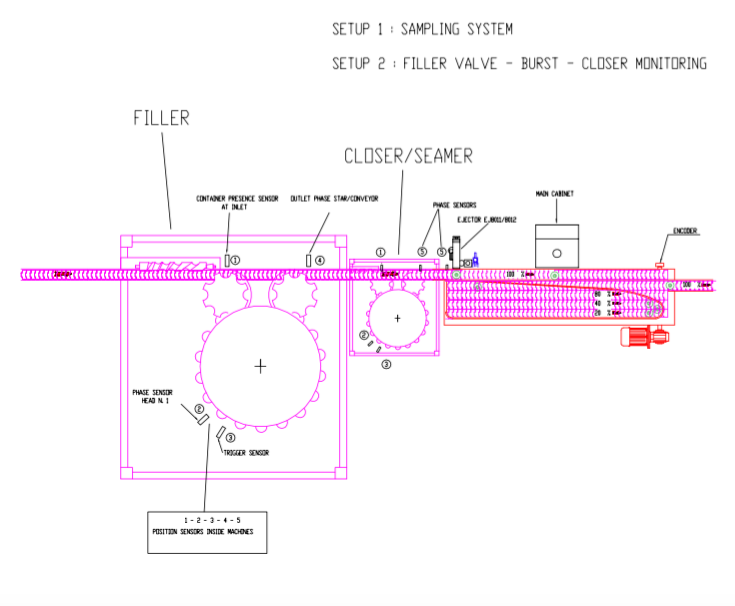

Monitoring of rotary machines and sampling

All of our control systems can be expanded with upstream machine monitoring functions.

ControlValve completes the level control with a filler monitoring software that displays the operating statistics for each valve. Essential for maintaining correct machine performance.

ControlBurst is a bottle burst/break control that allows the ejection of containers from the same filling valve or same capping turret in the rotations following the event. It is possible to extend the ejection to the nearby positions for a programmable number of containers.

The optional ControlCloser software allows the capper for the capping turret to be monitored. It has the task of signalling the position where operating problems are found.

ControlSampler is a system which allows samples to be quickly obtained for each single valve/head/rotary machine turret. Production downtime is eliminated and overall efficiency is increased; more reliable samples are obtained because they are taken under the actual operating conditions of the line. It is always advisable to have an ejector dedicated exclusively to this function.

Download technical documentation - Download

ControlCase

Control system for cases, bundles and cartons, of which the total weight is checked by identifying the absence of one or more packages inside or bottles that are not completely full.

Download technical documentation - Download

MultiPush Ejector

Electro-pneumatic system capable of gently diverting unstable containers of different weights and sizes onto parallel conveyor belts. Available in the Ejector and Divider versions.

VIDEO

Download technical documentation - Download

SinglePush Ejector

Electro-pneumatic waste device with single closed-cell pad, designed to divert containers of different weights and sizes onto parallel conveyor belts. Available in the ControlEjector STD and Multisize version.

VIDEO

Download technical documentation - Download

ControlData

Client-server database which maintains real-time display of all inspection data, alarms, events, and production batches of each configured system.

Download technical documentation - Download